AFR is a professional manufacturer with 15-year experience in high power handling fiber optic components and polarization maintaining components. Today we will introduce some characteristics and basic parameters of 300 mW 1550 nm isolator.

The polarization insensitive isolator is designed and manufactured according to Telcordia standard. The unique manufacturing process and optical path epoxy-free design enhance the device high power handling capability. The device is characterized with high performance, high reliability and low cost. It has been widely used in EDFAs, Raman amplifiers, DWDM systems, fiber lasers, transmitters and other fiber optics communication equipments to suppress back reflection and back scattering.

Spec table:

Related Reading:optic isolator,high power isolator,PM coupler

Optical fibers are designed for many different application scenarios. To understand the different applications, it is important to understand the properties of different fiber types.

Two major types of optical fibers exist for communication system: multimode fiber and single mode fiber. The difference between them is that multimode fiber can carry many modes of light rays while single mode fiber can only carry one mode of light ray.

Single mode fiber does have some disadvantages though. The smaller fiber core diameter makes it much harder to couple light into the fiber. This increases the manufacturing cost of many single mode fiber optic components such as isolator, attenuator, etc. Mini Manual Variable Attenuator The tolerances for single mode connectors, mechanical splices are also much more demanding.

One important variety of single mode fiber is polarization maintaining fiber, or also called PM fiber. PM fiber carries only one polarization (the light's electronic field direction) of the light. PM fiber's major applications include coherent communication system and electro-optic modulators which serves as a light transmitter in high speed fiber optic system.

Related Reading: 300 mW 1550 nm Isolator, 1550 nm Fused Tap Coupler, PM Filter Tap Isolator, High Power Polarization Insensitive Isolator

For those who are involved in the photonics industry and optical research, the difference between optical tables and optical breadboards may be quite significant. Learn how and why to differentiate between them.

Spontaneous decision might not always be the best ones, at least not when it comes to optical components. It's always better to have a clear opinion about what type of products you require, what are your alternatives, and the limits of your budget.

The more detailed information you acquire about optical breadboards and optical table, the more you would be able to make the best decision for your needs. So, get well informed about what to expect from services and prices in this industry and then start looking for a reliable manufacturer. Optical tables are made from a variety of metals and solid breadboards are most commonly made of aluminum. Both of these devices are meant to be rigid and stiff.

Comparing services and costs can help you take a profitable decision for your financial interest. It's a good idea to know your alternatives and then hire the services that comply with your demands and meet your expectations. So, surf the internet, get informed on what to expect from services and costs in this domain and see the latest advancements performed by optical industry developers. Remember that you can place customized requests and rely on assistance with taking a final decision when opting for optical elements.

Related Reading: discount high power isolator,polarization maintaining manufacturers,

High Power Polarization Insensitive Isolator, RG PM Fused Combiner

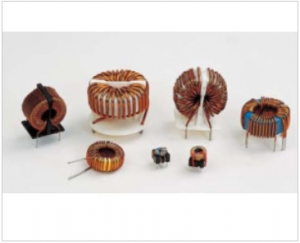

Different types of transformer are audio transformer, fly back transformers,high power transformer,push-pull transformer,current transformer, Electric transformer, Isolation transformer, step up transformer, and step down transformer.

Electric transformer is a device used to transfer an alternating current or voltage from one circuit to another circuit by way of electromagnetic induction. The simplest kind comprises of two coil of wire, insulated from one another and arranged to change the current in one coil would in turn produce a change in voltage in the other coil. A current transformer is a kind of electrical instrument that is produced particularly to provide a flow of current in the secondary circuit that is properly perpendicular to the amount of current flowing in its primary circuit. A high voltage transformer are generally used in power transmission applications, where voltages are very high sufficient to present a safety hazard.

Isolation transformer is a kind of current transformer which is used to supply power for equipments. Isolation transformer was designed specially by the manufacturers to meet the requirements of the business people and general users around the world for affordable prices. Low voltage transformer can be used as a magnetic low voltage transformer or electronic transformer. Low voltage transformers are mainly produced to reduce 120 volt line voltage to the secondary or the output voltage of the 12 volts. Fly back Transformer may be defined as an integrated transformer which implies it has built in rectifiers and divider networks and several low voltage windings. More information: www.amorphousbus.com.

Related Reading: Electric Current Transformers,Miniature Current Transformers,High Voltage Transformers

If you are keen to learn more about portable printers here are some of the advantages of them which might help you to decide whether one is right for you.

•They can be used when you are travelling. This is good news for anyone who travels a lot for business but needs to produce documents while they are on the road. So if you are someone who travels a lot for business this kind of printer could be exactly what you are looking for. In addition to these people who need to produce the quotes on the spot for customers in their own homes will find that this kind of printer is exactly what they have been looking for.

•Portable printers are not as expensive as many people think they would be. This is due to the fact that more and more companies who produce printers recognise that their customers need portable equipment at a reasonable price. So if you have been putting off buying this type of printer purely because you think it would be too expensive, take a look at the price ranges that they fall into and you could be very pleasantly surprised.

•Portable printers are much smaller than regular printers. Once again this is because they need to be taken from place to place with ease and as a result cannot take up too much room. So even if you need to use this kind of printer while you are on the train or travelling in the back of a car you will be able to do so with the minimum of fuss and disruption.

•Portable printers are capable of printing out several pages per minute, which means that you will not have to wait long for the documents you have requested to be printed out.

Related Reading:Portable Thermal Printer,POS Receipt Printer,Bluetooth Taxi Receipt Printer

The Electrical Power Transformer is in huge demand as the working of various industrial sectors requiring electric current has been simplified. Thus, cost effectiveness is also assured.

In the world of electricity and electronics, the Electrical Power Transformer is a very common name heard. It retains the balance in the distribution of electricity in circuits, machines and other sources requiring power for its running. The transformers are ideally designed to stabilise the fluctuation of voltage resulting in malfunctioning of the electrical equipments.

The main purpose of the Electrical Power Transformer is to increase or lower the voltage or the alternate current. When it comes to the construction of the transformer, there are two sets of coils termed as primary coil or secondary coil. These coils are linked around the magnetic field, acting as conductors. The number of windings in the coils determines the working of the transformer. The different types of power transformers like the Step-Up Transformer, Step-Down Transformers, etc., that are considered ideal to balance the electric current flow and make it appropriate for different household appliances and also for Industrial Machines.

The Electrical Power Transformer is delicately designed device. The components include connectors, porcelain assemblies, wire harnesses, off circuit tapping switches, and termination boxes. For better and hassle free operation, various accessories like wire harness or cable harness are also available. The time of installation is very crucial as the transformers require high amount of care. Moreover, the service quality could only assured with avoiding hazardous material and availability of moisture before final installation procedure. Thus, the Power Electrical Transformers have proved to be boon for various industries that require electric current for their workability.

Anhui Amorphousbus E-business Co.,Ltd is the China's first professional amorphous, Nanocrystalline products trading platform. Related to power transformers, miniature transformers, high frequency power transformers, inductors, magnetic materials and other five categories of products. More information:www.amorphousbus.com.

Related Reading:High Performance Inductors,Types Of Magnetic Materials,High Saturation Common Mode Inductance

A fuel cell is an electro chemical energy conversion device, which produces electricity from external supplies of fuel (on the anode side) and oxidant (on the cathode side). These react in the presence of an electrolyte to produce energy.

Welding of the plates is by far the most time consuming process involved in the manufacture of fuel cells - there is about one meter of welding required for every single plate in every single fuel cell stack - that is about 400m of welding for each eco-car. Optimising the welding process offers the opportunity to make significant savings in the cost of production of fuel cells.

The issues here are all related to the difficulty of achieving a small, clean, reliable weld at viable production speeds using traditional laser welding techniques. To solve these problems, the leading-edge manufacturers are now looking to fibre laser welding technology.

Results from leading manufacturers in this field show that fibre laser welding will play a significant role in tipping the balance for fuel cell technology from a 'promising idea' to a serious commercial solution to the world's energy-usage problems.

Related Reading; 1.0 μm Fiber Laser, 1064 nm In-line Polarizer, 1064 nm Bandpass Filter, 1064 nm Single Fiber Collimator

Fiber optic patch cable, often called fiber optic patch cord or fiber jumper cable, is a optical cable terminated with connectors on both ends. It has two major application areas: computer work station to outlet and patch panels or optical cross connect distribution center. They are for indoor applications only.

10Gig multimode fibers are specially designed 50/125 micron fibers optimized for 850nm VCSEL laser based 10Gig Ethernet. They are backward compatible with existing network equipment and provide close to three times the bandwidth of traditional 62.5/125 multimode fibers. 10Gig fiber cable jacket is usually aqua.

In some cases such as for long wave laser modules used in Gigabit Ethernet, modules need to operate for both single mode and multimode fibers, the mode conditioning fiber optic patch cables will fit for such situations.By allowing the single mode laser launch to be offset away from the center of the multi mode fiber the mode conditioning fiber optic patch cable reduces the effect of such differential mode delay.These cables are usually duplex type.

Related Reading: 1.0 μm Fiber Laser, 2.0 μm Fiber Laser Online, High quality 300 mW 1550 nm Isolator, 1550 nm Fused Tap Coupler For Sale, Wholesale PM Faraday Mirror

Rapid Sheet Metal, a dedicated rapid prototype sheet metal shop, is excited to introduce a new state-of-the-art fiber laser that will broaden the sheet metal prototype

shop's capabilities. Fiber lasers are 4-5 times faster than conventional Co2 powered lasers, and are able to cut thinner materials all the way down to 1/5000th of an inch. The new fiber laser will also allow Rapid to laser cut parts at a faster rate and with tighter tolerances compared to a traditional laser.

Operations Manager, Tom Bryk, said the fiber laser is a great addition to Rapid Sheet Metal, "We are able to give our customers better, more precise parts in half the time with our new fiber laser. Not only can we get a piece down to 1/5000th of an inch thick, we can now cut certain materials that we weren't able to before like bronze, brass, and copper."Rapid Sheet Metal is the world's largest Rapid Prototype Sheet Metal service. In business since 2001, with over 80 employees, and a 25,000 square foot facility, Rapid Sheet Metal always has the capacity to turn sheet metal fabrication rapidly.

Rapid Sheet Metal focuses strictly on providing sheet metal prototypes and time sensitive short run fabrications to new product developers and engineers. Typical quote response time ranges from instant to well under 24 hours and parts ship in one to two weeks. A 48-hour fast expedite prototype sheet metal service is also available. Parts such as brackets, racks, housings, and enclosures are fabricated to customer data from SolidWorks, Pro/E, SpaceClaim , Inventor, KeyCreator and other 3D CAD data sources from stainless steel, cold rolled steel and aluminum materials. Rapid Sheet Metal Inc's sister company, Rapid Machining, focuses on quick turn CNC machined and turned prototype parts.

Related Reading: Best PM Filter Coupler,Cheap PM Tap Coupler, PM Filter Tap Isolator, Hot Sale Port PM Circulator

Rapid Sheet Metal, a dedicated rapid prototype sheet metal shop, is excited to introduce a new state-of-the-art fiber laser that will broaden the sheet metal prototype

shop's capabilities. Fiber lasers are 4-5 times faster than conventional Co2 powered lasers, and are able to cut thinner materials all the way down to 1/5000th of an inch. The new fiber laser will also allow Rapid to laser cut parts at a faster rate and with tighter tolerances compared to a traditional laser.

Operations Manager, Tom Bryk, said the fiber laser is a great addition to Rapid Sheet Metal, "We are able to give our customers better, more precise parts in half the time with our new fiber laser. Not only can we get a piece down to 1/5000th of an inch thick, we can now cut certain materials that we weren't able to before like bronze, brass, and copper."Rapid Sheet Metal is the world's largest Rapid Prototype Sheet Metal service. In business since 2001, with over 80 employees, and a 25,000 square foot facility, Rapid Sheet Metal always has the capacity to turn sheet metal fabrication rapidly.

Rapid Sheet Metal focuses strictly on providing sheet metal prototypes and time sensitive short run fabrications to new product developers and engineers. Typical quote response time ranges from instant to well under 24 hours and parts ship in one to two weeks. A 48-hour fast expedite prototype sheet metal service is also available. Parts such as brackets, racks, housings, and enclosures are fabricated to customer data from SolidWorks, Pro/E, SpaceClaim , Inventor, KeyCreator and other 3D CAD data sources from stainless steel, cold rolled steel and aluminum materials. Rapid Sheet Metal Inc's sister company, Rapid Machining, focuses on quick turn CNC machined and turned prototype parts.

Related Reading: Best PM Filter Coupler,Cheap PM Tap Coupler, PM Filter Tap Isolator, Hot Sale Port PM Circulator